Linear Cans Filling Tshuab

Video

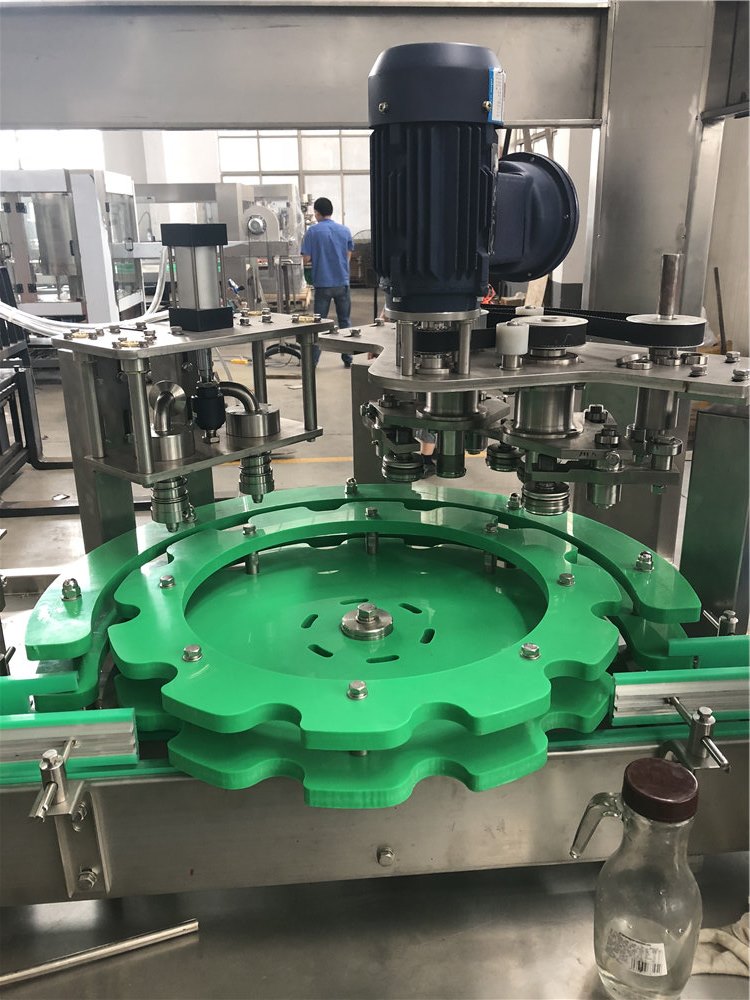

Kev piav qhia

Raws li ib qho ntxiv rau lub tshuab ua kom nrawm nrawm tuaj yeem ntim tshuab, cov kab ntim cov kaus poom tuaj yeem sau ntau yam khoom xws li: npias, carbonated / dej qab zib, kua txiv hmab txiv ntoo, dej qab zib thiab tshuaj yej.Vim nws cov hneev taw me me, cov khoom lag luam hloov pauv tau yooj yim thiab yooj yim tuaj yeem hloov pauv, yog li nws nrov dua nrog cov neeg siv me me.Piv txwv li, siv cov kab tawm tuaj yeem sau cov khoom siv tes ua npias yog lub tshuab me me, tab sis nws kuj muaj ntau yam kev ua haujlwm (kem cia tank, yaug, CO2 ntxuav, txhaws, hau, sealing).Cov haujlwm no tsis txawv ntawm cov tshuab ua teb rotary.Kuj tseem muaj lub sijhawm luv luv los ntawm lub npias filling, dai lub hau, yob sealing, uas ua kom cov pa oxygen nce siab hauv cov txheej txheem npias puv, kom ntseeg tau tias npias yog tshiab thiab tsis oxidized.Cov kev khiav haujlwm tshwj xeeb yog raws li hauv qab no:

Lub luag haujlwm ntawm lub tank yog los ntxuav cov plua plav thiab impurities hauv lub tank.Tig lub hub upside down, ces yaug lub hub nyob rau hauv siab siab nrog tshuaj tua kab mob los yog dej sterile, ces ntws lub hub.Lub tshuab ntxhua khaub ncaws tuaj yeem yog ib qho lossis ob peb, lossis nws tuaj yeem yog cov pa roj cua siab siab ntxuav thiab tshuab ziab khaub ncaws.

Feem ntau cov txheej txheem filling yog qhib filling, uas yog, lub filling valve txuas mus rau hauv qab ntawm lub peev xwm los sau, tab sis txoj kev filling no muaj ib qho me me uas tso cai rau qhov ntsuas kub thiab co2 cov ntsiab lus ntawm npias lossis carbonated dej haus.Txhawm rau hloov cov dej qab zib ntau dua los yog npias, peb tuaj yeem siv cov txheej txheem isobaric filling.Cov qib kua tuaj yeem kuaj pom los ntawm lub ntsuas ntsuas hauv qhov chaw, lossis lub ntsuas ntsuas dej tuaj yeem siv los ntsuas qhov tseeb dua.

Lub coiling system yog lub tshuab sealing uas tau tsav los ntawm servo lub cev muaj zog los tig lub thawv thiab tswj los ntawm hluav taws xob CAM.Nws muaj cov lus teb ceev ceev thiab siab sealing efficiency.Lub coiling yog tsim nyob rau hauv ib tug thib ob, uas yog sai npaum li cas ntawm pneumatic lub cev muaj zog coiling.Ib qho yooj yim los kho lub sealing lub log txoj hauj lwm, tuaj yeem raug kho raws li qhov chaw tsim khoom tau qhov tshwj xeeb ntawm yob sealing loj.Nyob rau tib lub sijhawm, hloov lub lauj kaub hom, lub hau kuj yooj yim rau kev khiav lag luam

Nta

1. Siemens tswj qhov system yog saws, nrog siab tsis siv neeg tswj muaj peev xwm, txhua qhov chaw ntawm kev ua haujlwm tsis siv neeg, tsis muaj kev ua haujlwm tom qab pib.

2. Cov khoom siv channel tuaj yeem raug ntxuav CIP kom tiav, thiab lub workbench tuaj yeem ntxuav ncaj qha, uas ua tau raws li kev cai huv ntawm kev txhaws.

3. Servo tsav sealing tshuab txhim kho kev ntseeg siab ntawm yob sealing, ua kom lub sij hawm sib khi, ua kom yooj yim rau kev teeb tsa thiab tu lub sijhawm, sijhawm.

4. Tib qhov kev lag luam-ua lub taub hau tshuab tshuab, Co2 tshem tawm kev ua haujlwm thiab Co2 ntim cov khoom tswj cov khoom siv nrog oxygen nce nyob rau hauv qhov yuav tsum tau muaj.

5. Yooj yim hloov ntawm ntau lub tank qhov siab thiab qhov dav.

6. Ob qho qhib filling lossis isobaric filling, lub ntim ntim tuaj yeem hloov kho los ntawm kev hloov pauv yooj yim.

7. Lub filling channel yog nruab nrog ceev / qeeb hloov valve kom ntseeg tau tias cov ntaub ntawv du thiab ruaj khov hauv cov txheej txheem filling.

Technical Parameter

| JMC1200-L (kua theem tswj) / F (flowmeter) 4-4-1 | ||

| Tsis muaj. | khoom parameter | Cov khoom siv tam sim no parameter |

| 1 | muaj peev xwm | 1200CPH (330ml) |

| 2 | zog | 1.8 kwm |

| 3 | tau ntaus ntawv |

decanting yuav tsum tau hloov kho lossis ntxiv kev hloov pauv, tab sis lub sijhawm xav tau yog luv heev) |

| 4 | cov khoom siv tshuab | Aluminium / stainless hlau 304 / nyuaj alloy / lwm yam khoom siv / kua kov qhov SUS304 / zaub mov qib yas |

| 5 | beer qhov kev xav tau | Kub: 30.2-32F (-1 txog 0 ℃) / Carbonation: 2.4 ~ 2.7 ntim CO2 / Siab: 22psi (0.15Mpa) |

| 6 | txoj kev filling | Qhib filling / xaiv isobaric filling, tus nqi ntxiv |

| 7 | txoj kev ntsuas | kua theem ntes / xaiv tau flowmeter filling |

| 8 | ua ntej sau CO2 tshuab siab | 0.2Mpa-0.3Mpa |

| 9 | CO2 tiv thaiv qhov tom qab sau | yog |

| 10 | huab cua regulator | 87psi-102psi (0.6Mpa-0.7Mpa) |

| 11 | hluav taws xob tivthaiv | Siemes ntse 200 |

| 12 | seamer | Pneumatically Tswj Sealing |

| 13 | yaj Oxygen | ≤ 50 hli |

| 14 | cia tank conveyor/rotary rooj | yog |

| 15 | yaug ua haujlwm | 4 lub taub hau ntxuav / tuaj yeem ua tau ntau dua, nyob ntawm qhov muaj peev xwm |

| 16 | tshuaj tsuag muaj nuj nqi | xaiv tau |

| 17 | khiav kev taw qhia | txoj kab ncaj nraim |

| 18 | CIP muaj nuj nqi | yog |

| 19 | tshuab loj | L1700 W1000 H2000 |

| 20 | coj lub sijhawm | 45 hnub / ib txheej thiab batch lub sij hawm yog hais txog tib yam / 45 hnub |

| 21 | nqe | 18W (yeem cov khoom siv nyiaj ntxiv) |